Factory Floor

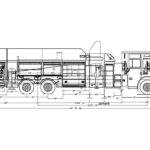

Custom built for the Refinery Terminal Company (RTFC)

Bulletpoint Specs

36-meter maximum vertical reach 118' 0"

102' 4" maximum horizontal distance from center of slewing axis

Rotating angle +/- 360 degrees

Self-supporting frame, torsion free FEM designed, and fatigue tested

Fully hydraulic outrigger controls on both sides of truck, with safety "Dead-Man" Switch

Front "X" style diagonal outriggers with single telescopic opening

Rear outriggers straight out, hydraulic out and down

Hydraulic locks on all four outrigger beams for transport

With 24" x 24" composite pads, light weight and easy to use

For pin point positioning with automatic locking brake (no drifting)

8" O.D. pipe starting at bottom of turret base (top of truck frame) to tip of boom, no pipe reduction

Vertically adjustable Monitor, Elkhart, adjustable stream Nozzle, flow capacity up to 5000-GPM

Two fully proportional radio controls, with small diameter hard wire cable as back-up, plus back-up hand controls on base.

Electrical controlled outriggers in addition to manual

Hydraulic cylinders on booms are provided with holding valves on all cylinders in both directions

Boom will have manual handles on main control valve in case of electric failure,

A diverter valve is to be built into main control valve to provide oil to outrigger valves

Flashing LED lights will be on all four outrigger legs to signify "out" position

Unit to be pressure checked, and stability tested

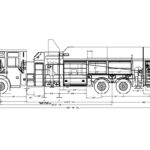

Chassis Model

Sutphen Monarch Chassis

100,000 psi 2-Channel Tandem Chassis Frame Rails, Domex Coated, 253” Wheelbase, Tow Eyes below Bumper

Cummins ISX-15, 600 HP Diesel Engine, with Jacobs Engine Brake, Primary and Secondary Fuel Filters

Top Air Intake with Ember Separator, Emergency Engine Shut-Down w/Reset

Ross TAS-85 Power Steering, Spicer SPL250 Severe Capacity Driveline, Tandem

Allison GEN-5 EVS4000 Automatic Transmission, Touch-Pad Shifter, Transmission Cooler, TRANSYND Fluid

Radiator Cooling Pressurized System for ISX15, Coolant Recovery, Fan Clutch, and Fire Pump Heat Exchanger

100-Gallon Stainless Steel Fuel Tank, Fuel Cooler, Remote Vented Fuel Fill, DEF Tank with Access Door

420-Amp Delco-Remy Alternator, six (6) Type 31 MHD Interstate 12-volt Batteries

Dana EFA245T, 25,500 lb. capacity Tubular Front Axle, Enhanced 25,500 lb. Front Suspension

Goodyear MICHELIN 445/65R22.5 G296A Front Tubeless Front Tires, 6” Front Meritor Cam Air Brakes

Meritor RT-60-180, 58,000 lb. 62,000 lb. capacity 68-60MPH Tandem Rear Axles, with Driver-Controlled Differential Lock

Raydan 58,000 lb. 62,000 lb. capacity Air-Ride Rear Suspension, 7” Rear Meritor Cam Air Brakes

Goodyear MICHELIN 315/80R22.5 G670 Highway Tread Tubeless Tires, 10-Tire Pressure Monitoring System

Alcoa Aluminum Polished Wheels, sized for 58,000 lb. 62,000 LB. Rear WR, 25,500 lb. Front WR, Hub & Lug Nut Covers

Air Brake System WABCO 6-Tanks, 1200 Air Dryer, 6-Channel Anti-Lock, Electronic Stability Control System

98” wide x 130” long (62” aft) 73” Aft 4-Door, 15” Raised Roof Custom Chassis Cab, w/Structural Integrity Certification

3/16” thick aluminum cab construction Hydraulic “Full-Tilt”, Manual Back-up, underside box tube sub-frame

Full Length Cab Doors, Manual Roll-Down Door Windows, Four (4) Auxiliary Cab Treadplate Aluminum Steps

Mid-Cab Side Sliding Windows, Synchronized-Intermittent Windshield Wipers,

Knurled Stainless Handrails: 4-Exterior Cab Sides w/Coat Hooks, Below Windshield, Interior Front & Rear Doors

Lang Merka 300-series Velvac Bus Style Door Mntd. Heated & Remote-Controlled Door Mounted Mirrors, Mirror Finish Stainless Front Grille

Front Bumper, Wrap-Around Polished Stainless Steel, Extended 24-inches ahead of Cab w/4-way Gravel Shield

Full Width Storage Well w/3-Deep Compartments, 1” Perimeter Lip and Hinged 2” High 4-way Aluminum Lid

Dual Grover 2040 Rectangular Air Horns Inboard Bumper, Activated Steering Wheel Button & Officer Dash

Whelen 295HFS2 Electronic Siren/PA, Two (2) Cast Products SA4201-68-A Electronic Speakers 1-Whelen Inboard Grille

Federal Q2-B Flush Grille Mounted Mechanical Siren, Activated Officer Dash + Steering Wheel Button

LED Front Headlights, Recessed into Combination Headlight/Emergency Light Stainless-Steel Housings

Whelen 400-series LED Front Turn Lights, 500-series LED Cornering Lights, Headlights Alternating Flasher

Cab Exterior: Mirror Finish Stainless Steel Scuff Plates. Aluminum Treadplate Scorpion Coating 2-tone Colored Rear Cab Wall

Cab Interior: Brushed Stainless Steel Interior Door Panels, Multispec Gray Speckle Paint, Gray Rubberized Floor

Full Size Engine Enclosure for ISX15, Scorpion Black Urethane Coated, Top Center Console w/Map Book Storage

12-Volt Electrical System Hard-Wired, Door Ajar Warning Light in Cab, High-Idle Switch, Multiple Power Points

Vehicle Date Recorder, Accessory Fuse/CB Panel, Power & Ground Studs, Interior Clear/Red Ceiling Lights

Severe Climate Heater, Air Conditioning, Defrosters with Full Windshield Ductwork

Air Ride Driver Bucket Seat, Air Ride Officer SCBA Bucket Seat, Three (3) Four (4) Crew SCBA Fixed Bucket Seats

Bostrom Secure-All SCBA Seat Brackets, 4-each, Seat Belt Warning System, Rolltek Side Curtain Airbags

Mid-Cab Interior Overhead Storage Cabinet with Lift-Up Doors D-Ring Latches, for 15” Raised Roof

Jensen Stereo HD AM/FM/WB Radio with CD Player, Multiple Front & Rear Ceiling Speakers

Safety Vision SV-CLCD Camera System, with 7” LCD Color Monitor and Multiple Cameras

Special Lighting: Under-Cab Ground Lights, Whelen Freedom 14-LED Lightbar, Six (6) M6 LED Warning Lights

FRC Spectra 20,000 Lumens 2-each Upper Side Scene Lights, FRC Spectra 20,000 Lumens 1-each Brow Light

FRC MAX Vision Tank Level Gauge LED Lights, Driver and Officer Upper Rear Sides of Cab

Two-Tone Cab Paint with Special Break Line

Accommodations for and Mounting of Cab Tilt Controls and Signage (at Mid-Ship Control Module)

Shore Air Inlet/Outlet Couplers, Air Pressure Gauge, and Enclosure with Access Door (Mid-Ship Control Module)

Additional Air Tank Reservoir for High Capacity Air Primer System

Air Tank Bleed Panel with Manual Drain Valves and Tubing for Seven (7) Air Tanks

Engine Exhaust Outlet Configured for Plymovent Exhaust Extraction System

Remote Stainless-Steel Fuel Fill Cubby Body Rear Wheelwell Housing with Access Door

Chassis Spicer Driveline Modifications to Accommodate Mid-Ship Split-Shaft Pump Transmission

Two (2) AC-44 Cast Aluminum Wheel Chocks, Rear Stainless Steel Clad Mud Flaps

Hot-Shift PTO with Spicer Driveline extending to Power Foam System Remote Mounted Hydraulic Pump

Apparatus Body

Polished Stainless Steel Outrigger Panels to be furnished, attached to/extending with Outriggers

Tandem Axle 3-Segment Pumper Tender Industrial Fire Apparatus Body, Compartmented with Hose Bed

Hose Bed Area, located Overhead the Foam Tank, Aluminum Floor Gratings

Double-Panel Natural Finish Brushed Stainless Steel Hose Bed Risers/Body Side Panels

Hose Bed Fall Arrest System with Six (6) Pivoting Slip-In Eyelet Style Anchor Points, Hose Restraint at Rear

Embossed 3/16-inch Aluminum Treadplate Rear Tailboard, with Stainless Steel Understructure

Integral Chassis Frame Rail Tow Eyes, Stainless Steel Tubular Body Subframe, Under-Floor Supports

12-Gauge 304-Stainless Steel Fabricated Apparatus Body and Compartments, All-Bolted Construction

Eight (8) Fully Enclosed Driver & Officer Side Compartments, with Painted Locking Style Roll-Up Doors

Compts: Filtered Vents, Adjustable Shelf Brackets, Door Bundle Encapsulators, Pull-Down Door Straps

Two (2) Heavy Capacity Roll-Out Aluminum Floor Trays, one (1) Adjustable Height Roll-Out Tray, Tray Tiles

Five (5) Adjustable Height Heavy Capacity Compt Shelves, Shelf Tiles

Four (4), 2-SCBA Bottle Compartments, located in 2-each Driver and 2-each Officer Side Wheel Well Housings

One (1) Wheel Chock Compartment, located in Driver Side Wheel Well Housing, for 2-Non-Folding Large Chocks

One (1) CENTER TNDMS, located in Officer Side Wheel Well Housing, for 2-AIR BOTTLES

Ten (1) Folding Steps, located: 2-each Driver and Officer Front Body Corners, 6-each Rear Driver-Officer Sides

One (1) Embossed 3/16-inch Aluminum Treadplate Intermediate Body Height, Rear Full Width Step

Four(4) outrigger panels. 2each side

Outrigger pad storage

Fire Pump System

Waterous TC-21 Chain Style Mid-Ship Mounted Fire Pump Split-Shaft Transmission

Pneumatic Fire Pump Shift with Remote Cab Controls and Mid-Mount Control Module Override

Lift-Up Bleeders and Drains for Suctions, Discharges, and Foam Manifold

Two (2) Suction Manifold Pre-Set Bronze Intake Relief Valves

Electronic Engine Governor for Pump Pressure Control, w/Digital Engine Instrumentation

Stand-By Dual (2) Discharge Pressure Relief Valves w/Pressure Single Control and Stand-By Electronic Throttle

Auto Air-Prime System, Three (3) each 2-Barrel Venturi’s and an auxiliary air reservoir

w/Rear Remote Prime Control & Gauge

Overheat Protection Manager, Pump Cooling System

Stainless Steel 12-inch Tubular Pump Suction Manifold with Three (3) Zinc Anodes

Three (3) 8-inch Pump Suction Intakes, reduced to 6-inch NST Male Fittings with Stainless Steel Strainers’

Three (3) TFT 12-volt Jumbo Ball Intake Valves, with Intake Relief Valves and Remote-Control Consoles

One (1) 2.5-inch Ball Gated Pump Suction Inlet

Pump Cooling Discharge to Ground-at Exhaust, Remote-Controlled

Stainless Steel 10-inch Tubular Pump Discharge Manifold with Two (2) Zinc Anodes, Two (2) 8-inch Branches

Stainless Steel 10-inch Discharge to Fire Boom Waterway, 8-inch 12V Butterfly Gate Valve, Remote-Controlled

Two (2) 2.5-inch Foam Capable Discharges, 1-Driver & 1-Officer Side, 12-volt 3.5-inch Remote-Cntrld Valves

Two (2) 5-inch Foam Capable Discharges, 1-Driver & 1-Officer Side, 12-volt 5-inch Remote-Cntrld Valves

Two (2) 6-inch Foam Capable Discharges, 1-Driver & 1-Officer Side, 12-volt 6-inch Remote-Cntrld Valves

Two (2) 4” Foam Capable Rear Deluge Discharges, 12V, 4” Remote-Controlled Valves

Two (2) TFT Y4-E21A, 2000-GPM Rear Monitors, 2-M-ERP Nozzles, and 2-YE-RF-900 Wireless Controls

One (1) 2.5 NST Foam Capable Front Bumper Extension Discharge, 12-volt 2.5-inch Remote-Controlled Valve

AccuMax-3300, Electronically Controlled Multi-Point Direct-Injection, 300-GPM Foam System w/Low-Flow

Stainless Steel Foam Suction and Discharge Manifolds, 6-inch Stainless Steel Foam Concentrate Strainer

Line Control High-Pressure Hose Assemblies, Hydraulic Servo-Controlled Foam Pump Drive with Oil Cooler

Two (2) 3-inch Foam Pump Gated Suctions, 1-Driver & 1-Officer Side, 2.5-inch NST Swivel Female Fittings

300-GPM Foam Tank-to-Foam Pump Ball Gated Suction, with Maintenance Blocking Valve

300-GPM Foam Pump-to-Tank Fill with Maintenance Blocking Valve

Combo Offboard Gated Discharge & Tank Fill

One (1) Master Control Display, Ten (10) Digital Line Control Displays, Manual Override, Low-Flow Option

Mid-Ship Top-Mount Pump Control Module, Dual Access Transverse Walkway

Transverse Hose Bundle Compartment, Driver & Officer Side Equipment Compartments

Full-Width Rear-Facing Top-Mount Pump Control Console and Instrument Panel, Standby Controls Cubby

Digital and Analog Discharge Line Instruments/Gauges, Analog Master Suction and Duplex Foam/Water Gauges

Three (3) 12-volt Power Distribution Panels: 2- Rear Water & Foam Pumps, and 1-Mid-Ship Electronics

LED Foam Tank Level Indicator, Two (2) LED Strip Light Foam Level Light Fixtures

LED Foam Tank Level Indicator, WLA-370-A at Rear of Body

Diesel Fuel Level Gauge, Air Horn Switch, and Color-Coded Gauge Bezels and Control Name Plates

Sweep-out floor in outrigger control area

Horizontal Sleeve or Notch Longitudinally Through Tank for 10-inch Feed to Fire Boom Waterway

One (1) 2.5-inch NST Swivel Female Gated Direct Foam Tank Bottom Fill, 12-volt 2.5-inch Remote-Controlled

Stainless Steel .5-inch Neoprene Rubber Lined Foam/Water Tank Cradle

Special Features

120-volt Gast Onboard Air Compressor

120-volt Onboard Powermax Automatic Battery Charger

Emergency Warning Devices

4-TIR500’s Upper/2-M6 Lower “C”, 4-M9 Upper (adjacent to Scenes), 4-M6 Lower “B & D” Wheel Well & Rear Corners

Traffic Directing 8-LED Light Array, with TACTRL Sequencer (LED Elements in Intermediate Full-Width Step Flange)

Four (4) LED Beacons located below the Horizontal Extending Outriggers

Four (4) LED M6 Warning Lights, located on Outrigger Cover Panels

Exterior Lighting

Surface Illumination, LED Fixtures: Runningboards, Tailboard, Walkway, Rear Intermediate and Folding Steps

Ground Lights, LED Beneath: Chassis Cab Doors, Mid-Ship Control Module, Apparatus Body Sides, Rear Tailboard

DOT Lighting, LED: Tail, Turn, Back-Up, Rear Marker, Side Marker, Upper Level Marker, Mid-Turn/Marker

LED Scene Lighting (in addition to Chassis Scene Lighting): 4-SPA-260-Q15 2-per Side, 2- SPA900 Rear

Four (4) SPA900 Scene Lights, located on outboard surface of the extending Outrigger Panels